Once the world capital of ceramics, Stoke-on-Trent has seen its pottery industry dashed to smithereens. David Nicholls meets the new breed of manufacturers who are picking up the pieces and putting its china back on the map.

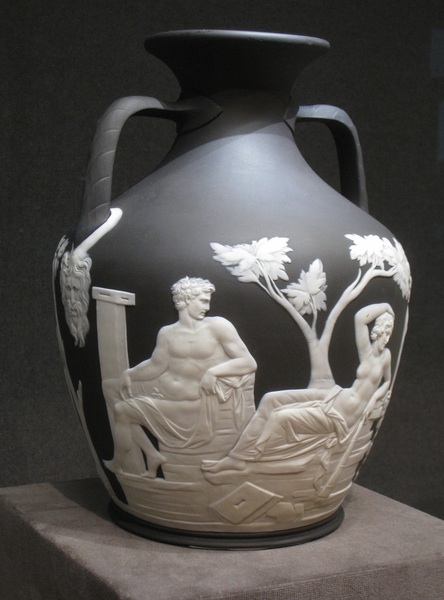

In the 18th century a fortuitous supply of clay, coal and canals coupled with the ambitions of great innovators such as Josiah Wedgwood propelled the ceramics industry of the Potteries – the group of six Staffordshire towns that would become the city of Stoke-on Trent – to the forefront of the Industrial Revolution. At its peak in the late 19th century the region was the epicentre of the world’s ceramic production, home to more than 2,000 kilns firing millions of products a year.

But within 100 years a sharp decline in British manufacturing, which led to the closure of mines, steelworks and factories, brought Stoke, and the industry that was integral to its identity, to its knees. As recently as the 1970s there were 200 factories still operating in the area; today there are about 30. Between 1998 and 2008 the Potteries lost more than 20,000 jobs. When Wedgwood – the sacred cow of Staffordshire ceramic production – called in the administrators and shut down its factory in 2009, it seemed to sound the death knell for the beleaguered industry.

The widespread hand-wringing about the state of Stoke-on-Trent is understandable, but thanks to a number of manufacturers who are staging a strong fightback we must avoid the urge to write the Potteries’ epitaph just yet. One of these is the formidable Emma Bridgewater, who came to the area in 1985 in search of a pottery to produce her designs. What she found was an industry in disarray, crippled by ‘bad 1970s-style management’. It was never her intention to be a manufacturer, but when the maker she had been using went bust in 1992 she stepped in and bought the factory, keeping its 35 staff on. Within five years her friendly, sponge-painted tableware designs (particularly her Polka Dot pattern) were in such demand that the company outgrew the premises and bought the much larger former Johnson Brothers factory on the Caldon Canal.

Today Bridgewater is the most high-profile member of Stoke-on-Trent’s new guard, and has championed British manufacture on television (Newsnight) and radio (Woman’s Hour), while the success of her company is a recurrent theme of newspaper business pages. What motivates Bridgewater is the unrealised potential that she sees in the region. ‘What we need to do is roll our sleeves up and get to work,’ she says. ‘And if we are going to make it here in Stoke-on-Trent, then we need to make it well. I’m not interested in making the cheapest mug.’

Her tactics are clearly working. At the end of the recession Emma Bridgewater’s profits were up by 40 per cent, and over the past 18 months she has increased her staff from 220 to 265. The company produces more than 5,000 mugs, bowls and plates every day. ‘I’m aware we are a global economy, but there is a lot to be said for jobs closer to home,’ she says. ‘Our success proves that companies really can still be successful at manufacturing in this country.’

Bridgewater’s husband, the artist Matthew Rice, is responsible for several of the pottery’s patterns, and for the past two years has been the company’s managing director. Rice is equally passionate – and outspoken – about the region. Two months ago he publicly criticised Stoke-on-Trent’s ‘feckless’ city planning and demanded that the council begin to regenerate rather than tear down the area’s historic buildings and factories.

A few miles down the road is the Portmeirion pottery, which was founded 50 years ago by Susan Williams-Ellis, the daughter of the architect Clough Williams-Ellis, who created the village of Portmeirion in north Wales. The pottery’s success is based on its casual earthenware tableware ranges, which account for nearly three quarters of the company’s ceramic business. Williams-Ellis’s most famous designs include the Totem and Magic City coffee services from the 1960s, but Portmeirion’s singular biggest earner is Botanic Garden. The pretty floral-and-leaf-bordered pattern, based on antique botanical illustration plates, has been in production since 1972.

When Portmeirion acquired the historic pottery firm Spode in 2009 (at the same time it also acquired Royal Worcester and Pimpernel, and formed the Portmeirion Group) it took the bold step of reversing the region’s manufacturing trend – it actually returned some of Spode’s production from China and Malaysia to Stoke. This was no mere marketing exercise or nod to sentimentality, but a shrewd business move. Today about 30 per cent of the products within Spode’s iconic Blue Italian range are once again being made in the same town where Josiah Spode established his company in 1770, and production is up some 20 per cent. As a result, 39 new jobs have been created and 15 of these have been filled by former Spode employees who had been made redundant when the firm collapsed.

On top of this is the belief is that the reinstatement of the Made in England stamp on the bottom of a Blue Italian tea cup will bring back some of the cachet that had been lost. Spode’s Woodland pattern from 1986 is lined up as the next design to be returned to the Stoke production line. ‘We are good at production,’ Julian Teed, the creative director of the Portmeirion Group, says. ‘And we are prepared as a company to spend money because investment in the factory is imperative if we are going to keep production in Stoke.’

In many ways the manufacturing process is the same as it was 200 years ago. In all, 22 pairs of hands will have touched each piece of pottery by the time it is packed and dispatched. But there have been significant technological developments that have increased efficiency and allowed Portmeirion to compete with other markets. In one area of the factory floor, robotic arms acquired from the car industry have been reprogrammed

to move heavy ceramic pieces from machine to machine. The company has also been thinking ‘green’ recently, which is somewhat challenging in an industry reliant on burning fuels in order to maintain extremely high temperatures. In the past 10 years the Portmeirion Group has cut its carbon footprint by about 40 per cent.

While Emma Bridgewater, Portmeirion and Spode illustrate how it is still possible to produce relatively high volumes for the mass market in Stoke, there is an equally significant number of smaller companies that are using the expertise and heritage of the region to produce work for a very different audience.

A particularly exciting example is the New English, a Stoke-based company that is more ceramics design house than manufacturer. It was set up in 2009 by Judith and Paul Bishop, who lived locally, had experience in creative and ‘innovations’ businesses, and were passionate about the area and its potential. ‘We could have bought a factory,’ Paul says. ‘But Stoke-on-Trent doesn’t need more capacity. What it needs is more demand.’ So he set about generating it.

The idea was to bring original modern designs to a local producer. Bishop sought out one of the most highly regarded fine bone china specialists in the area, Caverswall, to produce the goods. Although its reputation is excellent (it was awarded a royal warrant in 2008 and produces bone china for companies including Liberty, Paul Smith and Burberry) the Caverswall factory and its employees have had to be flexible in order to survive. For most, the working week is three to four days. But the partnership with the New English is providing an important new contribution to the workload.

The New English works with new names and independent designers, applying innovative decorations to classic ceramic shapes: Crusades by Terri McGettigan uses the imagery of the crucifixion and the war plane; Inkhead by Florian Hutter is a range that is ‘tattooed’ with rose and skull motifs. It may not be the place to look for a dinner service like the one your grandmother used, but it is being snapped up by design and gallery shops around the world. When Harrods decided to develop its own-brand fine bone china range, it turned to the New English to design and produce it. The result is the Knightsbridge collection, decorated in gold and platinum, which launched last month.

Like Bridgewater, Paul Bishop believes that the idea of competing with foreign producers on price is wrong. ‘We can’t compete with those volumes and maintain high-end production values,’ he says. ‘We are not competing with Ikea. The Far East can do great things, but their approach to design has some way to go.’ What each of these companies is proving is that it is possible to make a serious business in Stoke, and it is their ability not only to make but also to innovate that is securing their future.

There are other signs of hope amid the uncertainty in the area. A few months ago Burleigh Pottery – whose trademark blue-and-white ceramics are produced in the last working Victorian pottery in Stoke-on-Trent – was bought by the Derbyshire-based firm Denby. The company immediately recruited additional staff and has committed to keeping the factory going. And there is no denying the potential that a royal wedding can hold for any business with a commemorative memorabilia range in mind. Designers at Emma Bridgewater had samples ready within 24 hours of the announcement.

Breaking the mould

A selection of young designers who are looking to the expertise of the Stoke-on-Trent potteries to help realise their contemporary ceramic creations:

Andrew Tanner produces his own collection of ceramics and is also the head of design for the Stoke-based Royal Stafford and Poole Pottery. He was named Young Design Entrepreneur of the Year 2009 by the British Council (andrewtannerdesign.co.uk).

Reiko Kaneko is a tableware and accessories designer who adds a Japanese twist to traditional English fine bone china (reikokaneko.co.uk).

We Love Kaoru Kaoru Parry works with small independent family-run potteries to create her fine bone china pieces. Her work also includes elements that are helping to preserve dying skills in Stoke, such as ceramic flower making (welovekaoru.com).

Katy Potts The appropriately named designer specialises in teapots, some of which are hand-enamelled, a finish that was common in the 1920s and 30s. Each is made in Longton – an area of Stoke known for its makers of collectable teapots (katypotts.com).

By David Nicholls, Design Editor

Telegraph