What is a saggarmaker’s bottom knocker?

What’s My Line? was a Classic British television panel game from the 1950’s. Contestants with unusual occupations sign in, perform a mime of the job that they do, then field yes-or-no questions from four celebrities aiming to work out the contestant’s job.

The weirdest occupation on the programme is widely believed to be a “saggar maker’s bottom knocker”. Saggars are used to hold and protect pottery during kiln-firing, and by placing various substances in a saggar it is possible to produce dramatic visual effects on the finished pottery.

Producing saggars to the correct specifications required was a skilled job and needs a craftsman – the saggar maker. However, making the bases of the saggars is a less skilled job which can be left to a lesser craftsman, namely the saggar maker’s bottom knocker, who makes the bottom of the saggar by placing clay in a metal hoop and literally knocking it into shape.

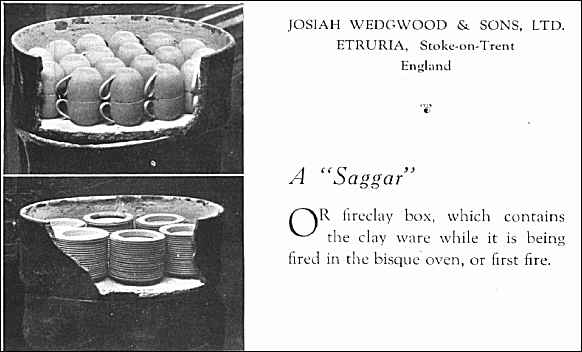

The saggar:

A SAGGAR is a fireclay container, mostly oval or round but sometimes oblong.

These are used to protect pottery from marking by flames and smoke during firing in a bottle oven.

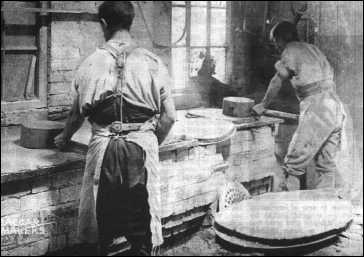

Frame filler:

The FRAME FILLER (usually a male apprentice) flattened a mass of clay and produced a rectangle which was wrapped round a drum to make the side of the saggar.

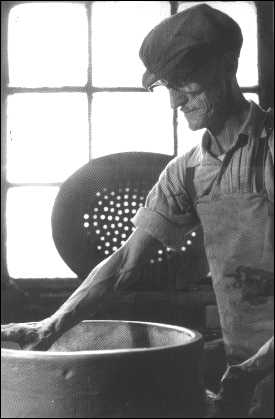

A frame-filler and a bottom-knocker at work side by side in the early 1900’s

A filled bottom ring on a shord (metal plate) sits on a lump of marl in the foreground.

Photo: Gladstone Pottery Museum

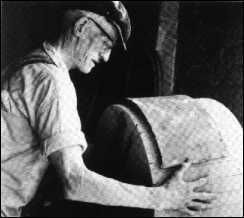

Bottom Knocker:

The BOTTOM KNOCKER (a young boy) made the base of the saggar from a lump of fireclay which he knocked into a metal ring using a wooden mallet or mawl (pronounced mow).

Pottery lads in 1921 with two mawls, the tool used for bottom knocking.

Photo: Gladstone Pottery Museum

The saggar maker:

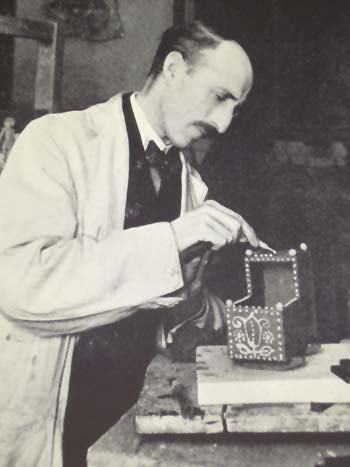

The SAGGARMAKER, is a skilled man, producing the finished saggar, using his thumb to make a near join between the side and the base.

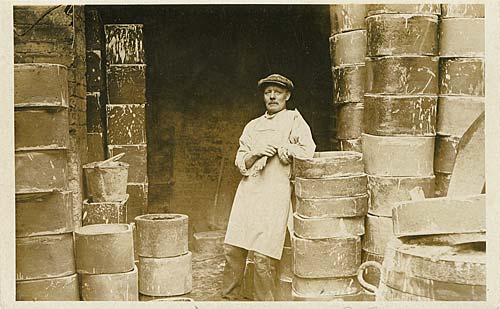

A saggar-maker at making the side of a saggar on a wooden former

Photo: Potworks

A saggar-maker assembling a base and side

Photo: Memories of Stoke-on-Trent

The finished saggars:

The finished saggar was fired in the kiln and lasted for 30 to 40 firings – if they were not broken

Placing wares in saggars required special knowledge. Plates were ‘reared’ or ‘dottled’; that is carefully separated from each other by thimbles to prevent the glaze from making them fuse together in the glost firing.

Saggars at Gladstone Works, Longton

Even after they couldn’t be used for firing the saggars were put to use………

Used saggars acting as walls at Lower John Street (c.1930)

Source: http://www.thepotteries.org