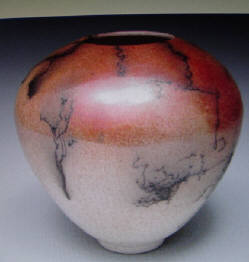

You may be familiar with it as ‘china’, but the ceramics category of antiques covers a surprisingly wide area of collecting, from functional pottery wares to highly prized pieces of porcelain.

Ceramics can be broadly divided into two main groups: pottery, which is opaque when held to the light; and porcelain, which is translucent. Within these two categories is a huge range of different wares which evolved over the centuries as new manufacturing techniques were developed.

If you’re just beginning your collection, the multitude of pottery wares produced during the 19th century could be an ideal starting point. During this period the Staffordshire area produced vast numbers of inexpensive household and decorative objects, which at the time cost a few shillings or less. These are still abundantly available and, although collectable, have remained relatively inexpensive.

“Porcelain has long been highly prized”

Porcelain has long been highly prized and tends to be more expensive than pottery. The field is divided into two main groups: hard-paste porcelain and soft-paste porcelain. Many pieces have marks of some type but these are no guarantee of authenticity because many factories copied each other’s marks to make their products more desirable. Value is usually a matter of size, age, rarity, decorative appeal and, above all, condition. European 18th-century porcelain tends to be very highly priced but you can often buy damaged pieces for a fraction of the cost of those in perfect condition.

When you first look at a piece of pottery or porcelain, an understanding of the materials and techniques used in its manufacture can help you identify its origin, date and how much it might be worth. The three main factors to assess are material, glaze and decoration.

Materials

Pottery

This has a relatively coarse texture compared with porcelain, and is usually opaque if held to the light. The two main types are earthenware and non-porous stoneware.

Earthenware

Clay fired at a temperature of less than 1,200°C (2,200°F) is classified as earthenware. The body is porous, and may be of a white, buff, brown, red or grey colour, depending on the colour of the clay and on the iron content.

Stoneware

This is made from clay which can withstand firing at a temperature of up to 1,400°C (2,250°F). The high firing temperature makes the clay fuse into a non-porous body which doesn’t absorb liquids, and may be semi-translucent. Bodies vary in colour.

Porcelain

If it’s slightly translucent the chances are it’s porcelain. Now you must decide which type – hard-paste or soft- paste. If the body looks smooth, like icing sugar, it’s probably hard-paste; if it looks granular, like sand, it’s more likely to be soft-paste.

Hard-paste porcelain

All Chinese and much Continental porcelain is hard-paste, and made from kaolin (china clay) and petuntse (china stone). First the object is fired, then dipped in glaze, then refired. The china stone bonds the particles of clay together and gives translucency. Because the firing takes place at a very high temperature the object attains the consistency of glass. The first hard-paste porcelain was made in China in the 9th century. In Europe, the Meissen factory began producing porcelain in the early 18th century, and before long, factories throughout Europe began making hard-paste porcelain.

Soft-paste porcelain

As the name suggests, soft-paste porcelain is more vulnerable to scratching than hard-paste. There are several types of soft-past porcelain, each made by using fine clay combined with different ingredients to give translucency. Soft-paste can often be identified because the glaze sits on the surface, feels warmer and softer to the touch and looks less glittering in appearance than hard-paste. Chips in soft-paste look floury, like fine pastry. In hard-paste porcelain, chips look glassy. Soft-paste porcelain was first produced in Italy during the 16th century. Later factories using soft-paste include St Cloud, Chantilly, Vincennes, Sèvres, Capodimonte and Chelsea.

As the name suggests, soft-paste porcelain is more vulnerable to scratching than hard-paste. There are several types of soft-past porcelain, each made by using fine clay combined with different ingredients to give translucency. Soft-paste can often be identified because the glaze sits on the surface, feels warmer and softer to the touch and looks less glittering in appearance than hard-paste. Chips in soft-paste look floury, like fine pastry. In hard-paste porcelain, chips look glassy. Soft-paste porcelain was first produced in Italy during the 16th century. Later factories using soft-paste include St Cloud, Chantilly, Vincennes, Sèvres, Capodimonte and Chelsea.

Bone china

This is a type of English porcelain first made c.1794 using a large proportion of bone-ash added to hard-paste ingredients. This body was used by prominent English factories such as Spode, Flight & Barr, Derby, Rockingham, Coalport and Minton.

Glazes

Glazes can be translucent, opaque or coloured. Hard-paste porcelain was given a feldspar glaze, which fused with the body when fired. On soft-paste porcelain the glaze tends to pool in the crevices. A variety of different glazes was used on pottery and porcelain. The main ones are:

Lead glaze

Lead glaze

Used on most soft-paste porcelain, and on earthenwares such as creamware.

Tin glaze

A glaze to which tin oxide has been added to give an opaque white finish.

Salt glaze

A glaze formed by throwing common salt into the kiln at about 1,000°C (1,800°F) during the firing.

Decorative techniques

Decoration can be added before or after glazing. Underglaze decoration means the colours have been added before glazing.

Underglaze blue

Blue pigment, known as cobalt blue, was used on Chinese blue and white porcelain, European delfware and soft-paste porcelain.

Overglaze enamels

Overglaze enamels were made by adding metallic oxide to molten glass and reducing the cooled mixture, which when combined with an oily medium, could be painted over the glaze and fused to it by firing. The range of colours was larger than the underglaze colours.