In the early part of the twentieth century, the prints, or lithographs, were of relatively poor quality: for example, a close examination of the printed colour areas on early designs such as Sèvres Marbling will reveal the individual ink dots which comprise the image. Similarly, close examination will usually reveal where prints have been joined, notably when several sections are used to make a border pattern such as towards the rim of a plate or a tureen. In the production process, slight imperfections could arise from these joints or from paper tears and these would have to be skilfully corrected by the decorators.

The design on an engraved printing plate for ceramic decoration would look exactly as the finished design on the pot: this is because the design is ‘lifted’ off the plate and then transferred onto the pot. Conversely, an engraved printing plate for a book would have the reverse of the final design: in this case the paper that lifts the design off the plate is the finished article; no ‘double transferring’ takes place.

The design on an engraved printing plate for ceramic decoration would look exactly as the finished design on the pot: this is because the design is ‘lifted’ off the plate and then transferred onto the pot. Conversely, an engraved printing plate for a book would have the reverse of the final design: in this case the paper that lifts the design off the plate is the finished article; no ‘double transferring’ takes place.

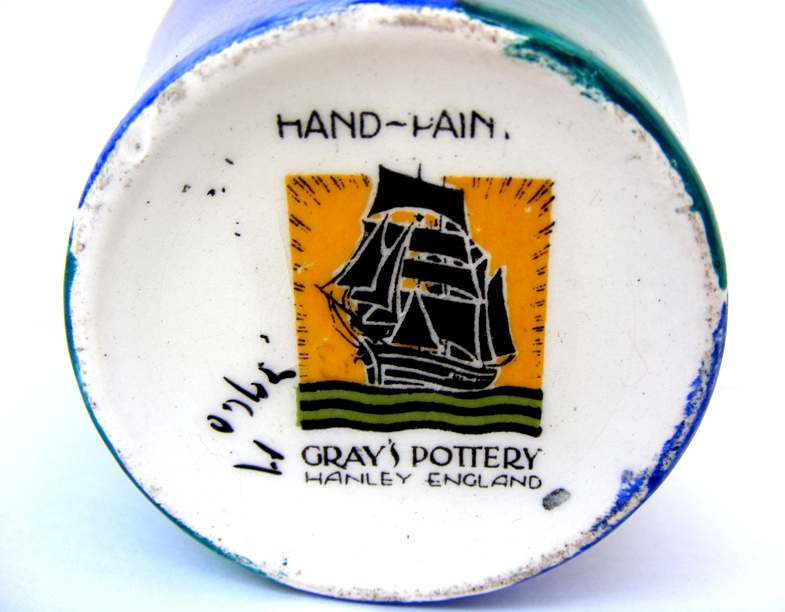

Throughout the company’s life, Gray’s Pottery produced designs which incorporated prints in various forms. This is a common decorative technique in the pottery industry, one that is still in widespread use. In the context of Gray’s Pottery, this idea may seem strange because the company used the words hand-painted in its advertising and, in particular, as part of its backstamp. How can hand-painted be associated with a print? The answer is that it can be used in conjunction with a print.

Imagine the process which a child uses in a colouring-book. She or he fills-in an outline of a picture. This is exactly what the pottery decorator can do: using enamel colours to fill-in a printed outline.

In contrast to the process of ‘complete’ hand-painting, where a design is applied to a naked pot, the process of ‘print and enamel’ enables the production of a more accurate and consistent interpretation of a design, particularly in operations where a number of decorators is involved. During the 1930s when at its most productive, Gray’s Pottery probably had around 35 decorators.

In contrast to the process of ‘complete’ hand-painting, where a design is applied to a naked pot, the process of ‘print and enamel’ enables the production of a more accurate and consistent interpretation of a design, particularly in operations where a number of decorators is involved. During the 1930s when at its most productive, Gray’s Pottery probably had around 35 decorators.

The actual production of the outline print can be achieved in a number of ways. Gray’s Pottery used two distinct print processes as described below. Note that the information relates to on-glaze decoration ie the company always bought its ‘white ware’ plain but already glazed.

Prints by lithographic transfer – a common process throughout the first half of the 20th century. A stone (originally) or, later, a metal plate (usually copper), has the design engraved in its surface. The engraving is then filled with colour and a transferring medium (usually thin paper) is pressed onto the surface. By doing this the design is transferred to the paper which is then pressed and rubbed firmly onto the pot. The paper burns away during the firing process leaving the design fixed just on or within the glaze.

Prints by so-called ‘cover-coat’ – the print design is held together by a plastic backing which burns away in the firing. This process was developed for the ceramic industry in 1957.