SHEFFIELD, England (1773 – Present)

Sheffield Assay Office

Guardians’ Hall

137 Portobello Street

SheffieldS1 4D S

United Kingdom

Telephone: +44 (0) 114 275 5111

Facsimile: +44 (0) 114 275 6473

There has been an Assay Office in Sheffield since 1773 when local silversmiths, who resented the inconvenience of having to send their wares to London for hallmarking, joined with Birmingham petitioners to ask Parliament for their own Offices. Despite fierce opposition from the London Goldsmiths’ Company, an Act of Parliament (shown here) was passed, granting Sheffield the right to assay silver.

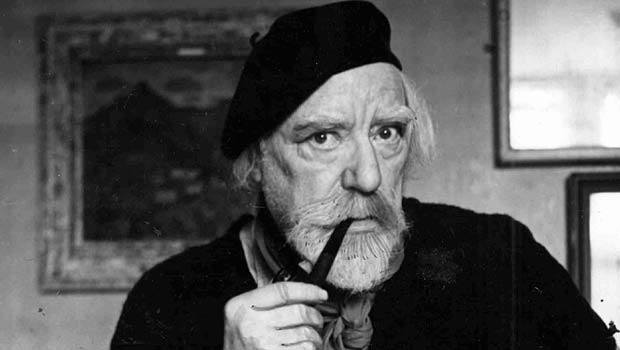

Because the Select Committee which considered the petition had uncovered so many abuses by the existing Assay Offices of the time, Parliament made sure that the new ones were more strictly controlled. The Act appointed thirty local men, including Thomas, the 3rd Earl of Effingham (shown below) as ‘Guardians of the Standard of Wrought Plate within the Town of Sheffield’ to supervise the work of the Office.By restricting the number of Guardians who were silversmiths to fewer than ten, Parliament also made sure that the Office was run for the benefit of the consumer rather than the manufacturer.

Because the Select Committee which considered the petition had uncovered so many abuses by the existing Assay Offices of the time, Parliament made sure that the new ones were more strictly controlled. The Act appointed thirty local men, including Thomas, the 3rd Earl of Effingham (shown below) as ‘Guardians of the Standard of Wrought Plate within the Town of Sheffield’ to supervise the work of the Office.By restricting the number of Guardians who were silversmiths to fewer than ten, Parliament also made sure that the Office was run for the benefit of the consumer rather than the manufacturer.

The day to day running of the Office was entrusted to an Assay Master who had to take his oath before the Master of the Royal Mint and enter into a Bond for £500. The Office was to be non-profit making and its running costs were to be met by the hallmarking charges paid by the manufacturers.

More than two hundred years later, the Office is still funded in exactly the same way.

Originally, Sheffield had the right to mark all silver goods produced within a twenty mile radius of Sheffield. After the second Sheffield Act of 1784, the Office also had the right to keep a Register of all makers’ marks (shown below) on plated silver wares made within one hundred miles radius – which of course included Birmingham.

From 1836 this Register unfortunately fell into disuse, but before then Sheffield and Birmingham frequently quarrelled over Sheffield’s monopoly, and Sheffield occasionally threatened to prosecute Birmingham makers for using unregistered marks. Possibly this explains why more Birmingham platers than Sheffield registered their marks.

The 1773 Act had empowered Sheffield to use a Crown for its town mark. The story goes that this was because the Birmingham and Sheffield petitioners for the Act met at the ‘Crown and Anchor’, an inn situated off The Strand in London, and that each town adopted one of these signs as its mark. Certainly the inn existed – but whether there is any truth in the story is unknown. After 1903, when Sheffield was finally allowed to assay and mark gold as well as silver (the result of a clause in the Sheffield Corporation Act), Sheffield had two town marks – the Crown for silver and the Rose for gold.

For the first eleven years the Sheffield Assay Office struggled to survive, borrowing heavily from local silversmiths. By using mass-production methods for stamping out thin silver, Sheffield made very light wares which competed strongly with heavier London-made goods. Assaying, however, was charged for by weight. Over 100 knife handles (shown below) could be marked for only five pennies – a price which did not reflect the time and effort involved. The only way to make ends meet was to increase charges. The Act of 1784 charged for small articles by count instead of weight. As a result, the Office’s fortunes revived.

The first Assay Office was a rented house on Norfolk Street and the first Assay Master a Londoner, Daniel Bradbury. The Office only opened on Mondays and Thursdays, although Mr. Bradbury was allowed to open on a third day for private assays.

In 1774 the Office moved to a court off Norfolk Street “lately occupied by Thomas Boulsover” – the inventor of Old Sheffield Plate. By 1795 the Office had moved again, this time to a brand new building on Fargate (shown below).

In the nineteenth century, Sheffield became a major manufacturing centre with an international reputation for its silver and cutlery. Production continued to grow rapidly and it became obvious that the Office could no longer cope unless its opening hours increased. When, in 1880, the Fargate premises were needed for road-widening, the Guardians acquired a new site in Leopold Street (shown below) and remained there until 1958. By this time, however, the demand for silver goods had fallen dramatically and the building was much too large.

Before the World War II, 1,250,000 ozs of silver passed through the Office each year.

By 1958 this had fallen to 300,000 ozs. Many large local firms closed and it seemed as though the only people still making silverwares were skilled craft-workers. The Office moved again, this time to a much smaller building in Portobello Street (shown below).

After the Hallmarking Act was passed in 1973, the nature of the work submitted to the Assay Office changed. No longer were the main customers the traditional Sheffield silversmiths producing large pieces of hollow-ware. Goods from all over the United Kingdom and abroad came in to be assayed, and foreign gold (especially 9ct gold chains) became very important. The extra workload involved by this increase in smaller articles necessitated re-development – initially within the existing building, to streamline the laboratories and make more marking space.

In 1973, Jack Cheetham made some cufflinks (shown below) in which the hallmark was a necessary and important part of the decoration; Jack Spencer adapted this idea and used the largest size of hallmark as decoration on a range of gold and silver jewellery.

A cheaper alternative then appeared, in which the mark was placed vertically down a rectangular block to make ‘dog-tag’ pendants, and these, especially when they incorporated the Special Mark (shown below) to celebrate the Queen’s Silver Jubilee, became phenomenally successful.

The income from this extra work was used in alterations to make the Goldsmiths’ Wing to create more marking space, and the foundation stone was laid by Ian Threlfall, Prime Warden of the Goldsmiths’ Company, in October 1978. More space for marking was created by renting office space elsewhere in the town and converting the existing offices into marking rooms. Meanwhile, the Office bought the former ‘Willow Tree’ public house next door and fitted it out for offices and marking. By now the British Hallmarking Council was pressing for an expansion of hallmarking facilities in Britain, so the Office also bought the Charleston Works on Orange Street adjacent to the ‘Willow Tree’ room for more building.

In March 1983 Sir Frederick Dainton, then Prime Warden of the Goldsmiths’ Company, laid the foundation stone of the Guardians’ Hall. The new building was completed in 1985 and officially opened by Her Majesty Queen Elizabeth II (shown below) in December 1986. It provided extra space for offices, laboratories, staff facilities, Board Room and Library.

The Hallmarking Act of 1973 removed many restrictions on marking and consolidated many earlier Acts. It was based on the Trade Descriptions Act and made it an offence to sell almost anything as gold, silver or platinum unless first assayed and marked. For the first time, all the Offices adopted the same date-letter and alphabet. After 200 years, Sheffield lost its Crown mark for silver and used the Rose on both gold and silver. Platinum was not assayed in Sheffield until June 1975, mainly because of the cost of the equipment needed, but testing and marking were finally introduced to meet local customers’ demands.

Throughout its long and fascinating history, the Office has continued to adapt to customers’ needs and to introduce innovative new processes.

In 1997 laser marking was introduced for hollow and delicate articles such as necklaces, watch-cases and bangles, which would have been damaged by traditional ‘punching’ methods.

Other services, such as nickel-free testing for jewellery and mercury-screening for occupational exposure, complement traditional assaying and hallmarking.

January 1999 saw the introduction of additional (lower) standards for gold, silver and platinum to enable free competition within the European Community. For the first time the date-letter became voluntary rather than compulsory, and the sterling lion mark and crown gold mark also became optional. Now all goods are marked with their standard of fineness in parts per thousand, and it is no longer possible to distinguish between British and foreign-made articles.

In 2007, the introduction of new legislation for ‘mixed metals’ marking meant that items such as jewellery and watches that are made from a combination of metals such as silver and titanium or gold and stainless steel could now be hallmarked.

Sheffield Assay Office had lobbied hard to bring about the legislation, seeing it as of particular relevance to contemporary designers working with mixed metals and providing greater scope and encouragement for them to explore more creative designs. The changes also benefit retailers and consumers alike, as a mixed metal hallmark is an endorsement and authentication of content.

Whilst assay and hallmarking continues to be an important part of the Sheffield Assay Office business, an ongoing investment in research and development has seen the the organisation move into advanced analytical services – with clients that range from high street retailers of fashion jewellery to international healthcare companies.

The significant growth of this business has prompted yet further investment – in a purpose-built single storey assay, analytical and research facility to which the Sheffield Assay Office moved in July 2008.

More than 220 years after it first opened its doors, Sheffield Assay Office still protects consumers and manufacturers alike, maintaining its reputation for integrity and efficiency.

We are proud of our history but we will always move with the times too.

HISTORY INTEGRITY INNOVATION

There has been an Assay Office in Sheffield since 1773, when local silversmiths successfully petitioned Parliament for the right to assay silver in Sheffield.

There has been an Assay Office in Sheffield since 1773, when local silversmiths successfully petitioned Parliament for the right to assay silver in Sheffield.

To ‘assay’ means to test and assess the precious metal content of an item.

It is impossible to tell the precious metal content of an item just by looking at it. Gold, silver and platinum are too soft to use alone for making jewellery, cutlery and other goods. They need to be alloyed with other, baser (and cheaper) metals for manufacturing. To protect the consumer, we test articles to make sure that too much base metal has not been used. At the same time, we ensure the manufacturer’s peace of mind by providing an independent assessment of quality and content.

The 1773 Act of Parliament appointed 30 local men as ‘Guardians of the Standard of Wrought Plate in the Town of Sheffield’ to supervise the work of the Office.

Even as early as 1773, Sheffield already had an established tradition of fine silverware production so it was interesting, but entirely appropriate, that the number of Guardians who were also silversmiths was restricted to just ten to ensure that the Office offered an independent and impartial service – and was run for the benefit of the consumer rather than the manufacturer. After all, the hallmark is the oldest form of consumer protection that exists.

So, almost two and a half centuries ago and right at the start of its long and fascinating history, The Sheffield Assay Office put a marker down for independence and integrity. In those early days, most of the assay business came from within a 20 mile radius and precious items were literally presented ‘over the counter’ to be assayed.

Today, The Sheffield Assay Office attracts customers from all over the world and the business has evolved to meet the demands of society and industry. Jewellery and items of precious metal are still assayed in their millions each year and bear the distinctive Sheffield ‘Town’ mark, but Sheffield Assay office now has a world-wide reputation in other arenas too, particularly in cutting-edge analytical services.

INTEGRITY

From a past rooted in the history of craftsmanship to a present and a future which embraces innovation, The Sheffield Assay Office has built a reputation for integrity in every respect.

The traditional business of hallmarking continues to provide customers both nationally and worldwide with an assurance of quality and purity; the instantly recognisable Sheffield mark of the rose is carefully applied to items of precious metal which can range from the most delicate chain to a stunning one-off table centrepiece created by a contemporary designer. Whatever the item, whoever the customer, the independence and stringent standards of The Sheffield Assay Office ensure accuracy and inspire confidence.

The Sheffield Assay Office was also one of the driving forces in bringing about legislation for the marking of mixed metals; items that are made from a combination of precious and non-precious metals can now be hallmarked to offer consumers more accurate descriptions of the items they are purchasing.

The guiding principles of protection and guarantee have also enabled The Sheffield Assay Office to move successfully into other areas of analysis where, once again, a independent assessment is required.

The Analytical Services division not only provides metals analysis and certification but also operates in areas as diverse as smelting and assay of bullion, mineral analysis and land contamination investigations, mercury screening and medical research, plating thickness measurement and nickel testing.

Clients for these services are drawn from a diverse range of business and industry but they share a common need – for absolute integrity of service and evaluation.

INNOVATION

Craftsmanship has provided the cornerstone for the growth of The Sheffield Assay Office and there is still a need for traditional hallmarking skills; by hand is often the best way to hallmark certain items which range in scale from very small to large but irregularly shaped. Skill and care are part of the heritage of the Ofiice – and will play a key role in the future too.

The advent of laser marking, however, has meant that delicate or hollow articles can be hallmarked without any possibility of damage and The Sheffield Assay Office has invested significantly in lasermarking technology for both quality and quantity of output.

Laser marking also has applications in other specialist areas, where clients include major automotive manufacturers and tool makers.

In other areas of the organisation, investment and innovation also provides the impetus. The laboratories are superbly equipped with leading-edge technology and staffed by highly qualified personnel who can, for example, determine the composition of a soil sample, screen for mercury, provide valuable data for the medical profession or test costume jewellery for nickel according to the EC Directive.

Investment in XRF (X-Ray Fluorescence) machines has ensured that Sheffield Assay Office Analytical Servcies can deliver very accurate analysis of metal composition and material conformity.

Clients include national high-street retailers and international manufacturers.

Sheffield Assay Office was one of the first laboratories to be given UKAS accreditation and is proud to have retained that accreditation continuously for 30 years, each year satisfying the stringent demands of the standard.

For clients, many of whom must demonstrate Due Diligence, this commitment to quality and continuous improvement is seen in a concise service, confidentiality and comprehensive reporting.

In more than two centuries of history, The Sheffield Assay Office has proudly maintained a position of independence and integrity. Today, a reputation for innovation too provides a compelling reason for business and industry across the spectrum to use the services in delivering consumer protection.

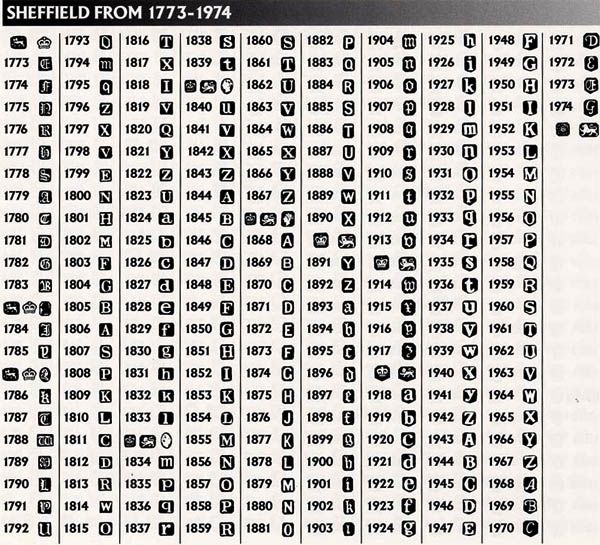

TABLE OF SHEFFIELD DATE LETTERS •

City of Sheffield – 1894 Maker Walker & Hall, Sterling

Sheffield Date Letters • 1773 – 1974

The shape of the shield cartouche around the City Mark and Standard Mark generally change to match the shield around the Date Letter Mark.

SHEFFIELD MAKERS’ MARKS

| AH | Aaron Hadfield | JC NC | J & N Creswick |

| DH & Co | Daniel Holy & Co | JD & S | James Dixon & Sons |

| D & S | Dixon & Sons | JR | J Round & Son |

| GA & Co | George Ashforth & Co | MF RC | Fenton, Creswick & Co |

| GE & Co | George Eadon & Co | MH & Co | Martin Hall & Co |

| HA | Henry Archer | NS & Co | Nathaniel Smith & Co |

| H & H | Howard & Hawksworth | RM | Richard Morton |

| HE & Co | Hawksworth Eyre & Co | RM & Co | Richard Morton & Co |

| HT | Henry Tudor | RM EH | Remy Martin & Edward Hall |

| HW & Co | Henry Wilkinson & Co | S & N | Stafford & Newton |

| IG & Co | John Green & Co | SR & Co | Samuel Roberts & Co |

| IH & Co | J Hoyland & Co | T & IS | T & I Settle |

| IL | John Law | TJ NC | TJ & N Creswick |

| IP & Co | John Parsons & Co | WD | William Damant |

| IR & Co | John Roberts & Co | WF AF | Fordham & Faulkner |

| ITY & Co | John T Younge & Co | W & H | Walker & Hall |

| IW & Co | John Winter & Co | ||

| JB | James Burbury |

Credit: http://www.assayoffice.co.uk