To be sold as Silver or any other precious metal, all finished items must undergo tests carried out by the assay office. There are four Assay offices in the UK (London, Birmingham, Sheffield and Edinburgh) and each undertakes tests to ascertain the precise metal content of the items delivered to it to ensure they comply with the law.

The Sterling Silver standard requires all of the metal making up an item to contain 925 parts pure Silver to the 1000.

When an article of Silver doesn’t comply with the required standard the assay offices can (and do) destroy the object and the Silversmith has some explaining to do. Although it has to be said that most cases are a result of miscalculation. For example, if the clip of a pen is not made of silver, but the rest of the pen is, then the Assay office would not hallmark the object if by their calculation the whole pen (clip an all) melted down would not still contain 925 part pure silver.

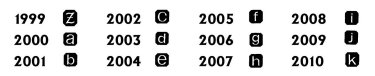

In 1999, a new format of English hallmarking on objects of Sterling Silver was initiated consisting of a maker’s mark, the assay office insignia and a 925 symbol. Optional extra marks are the ‘Lion Passant’, the UK sign of Sterling Silver, and the date letter stamp. The standardising of the date letter sequence, shared by all four remaining assay offices in Birmingham, Edinburgh, London and Sheffield, were introduced to bring the UK system closer in line with other European Union standards.

Assaying and Stamping Hallmarks

The basic method of assaying, also known as the ‘Cupellation’ process, was first introduced by the ancient Egyptians. The process starts with a small sample of Silver being removed from the object to be tested, which is then carefully weighed and measured.

The sample is placed in a Cupel, a small crucible made of bone ash, along with a small quantity of lead. This is then heated in a furnace. The lead and any other base metals contained in the silver sample are either oxidized or absorbed into the Cupel, leaving only the pure silver behind.

The remains of the silver are then weighed and measured and compared to the initial weight of the sample. The Cupellation process is the most accurate method for determining metal purity and is still the standard technique practiced today – although electronic and chemical tests are now common for small and delicate items. Upon meeting the required standards of Sterling Silver the item of Sterling is stamped with the appropriate hallmark.

Until quite recently, most Hallmarks were ‘Struck’ using steel punches. The punches are produced in various proportions, appropriate for petite pieces of jewellery to hefty items of Silverware. Punches are made in straight shanks for normal punching with a hammer, or ring shanks used with a press to mark rings.

The problem with traditional punching is that the procedure can distort the form of the item being marked, resulting in the article having to be reworked after hallmarking is completed. For this reason unfinished ‘rough’ items of are often sent to the assay office where cuts-offs are taken and tested from the articles before hallmarking is executed and the item returned for final polishing.

A recently introduced method of marking is uses laser technology, which burns the hallmark into the silver, something which is especially valuable for delicate items which would otherwise be damaged by the traditional technique of punching. This procedure of hallmarking uses high power lasers to evaporate material from the surface. There are two methods of laser marking, 2D and 3D, 2 dimensional marking burns the outline of the hallmarks into the object, while 3 dimensional marking simulates the traditional punching.

Hallmarks on Silver

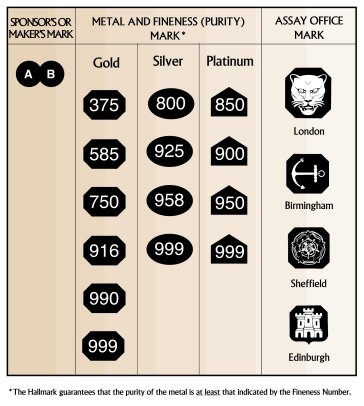

The numbers 925 or the word silver seen alone on modern articles for sale proves nothing. This is an international mark called a Convention Mark and may have been put on by the maker in some far flung corner of the globe – it does not mean that the item has been tested by an independent body. Authentic British Sterling Silver, Gold or Platinum hallmarked items usually carry a minimum of 3 and up to 5 different stamped symbols. They can only be applied by an official Assay Office after the item has been tested.

As we also sell items made of gold, here is a quickie tour of current hallmarking that you should find on all precious metal items, except those under a certain threshold weight (6 grammes in the case of sterling silver).

Until 1998, a Hallmark consisted of four COMPULSORY MARKS. Since 1998 the date letter has become optional but the other three symbols remain compulsory. The symbols give the following information:

- Who made the article

- What is its guaranteed standard of fineness

- The Assay Office at which the article was tested and marked

- The year in which the article was tested and marked

Sponsor’s Mark (formerly known as the Maker’s mark)

![]() This shows the person or company responsible for sending the article to the Assay Office. Each maker has their own mark designed and registered at the Assay Office, which keeps a variety of stamp sizes to use on that silver or goldsmith’s items.

This shows the person or company responsible for sending the article to the Assay Office. Each maker has their own mark designed and registered at the Assay Office, which keeps a variety of stamp sizes to use on that silver or goldsmith’s items.

Standard Marks

These show the standard of fineness – the purity of the precious metal, in parts per thousand. Eg: The background shape shows the metal. The number shows the articles purity as parts per 1000. Gold and silver come in several purities and platinum as one, which is 95% pure.

Assay Office Mark

There are now only four British Assay Offices in existence, but there have been more in the past. Birmingham, London, Edinburgh, Sheffield.

Optional Marks

In addition to the Compulsory Marks a sponsor may wish to incorporate any of the traditional marks which have been struck on British articles over the centuries and which have been recognised throughout the world. In the case of Braybrook & Britten , we try to mark everything with the full traditional set of hallmarks including the date letter – a marvelous way of giving a gift to commemorate a special year. But be warned. If you want a piece of silver marked for a particular year, it has to be in hall before the end of December as date letters are never back dated.

Date Letters

Credit: http://www.braybrook.co.uk