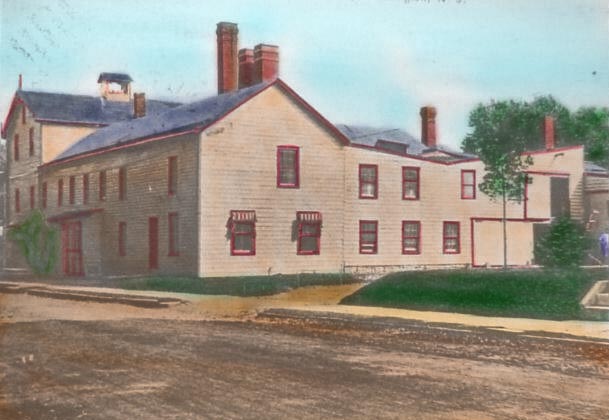

The company that became Fulper Pottery was begun in 1814 in Flemington, New Jersey by a young Samuel Hill, a potter originally from New Brunswick, New Jersey. Hill was a utilitarian potter and Hill Pottery produced drain pipes and storage crocks and jars from Flemington’s red earthenware clay.

Upon Samuel Hill’s death in 1858, pottery worker Abram Fulper began purchasing Hill Pottery from the Hill estate. By the 1860s, the company now owned by Abram Fulper (also known as Abraham) was called Fulper Pottery. By this time the company was producing an assortment of earthenware, stoneware and tile products.

Abram Fulper’s sons continued the pottery after his passing. The company became known as Fulper Bros. or Fulper Bros. & Co. during the 1880s. Products continued to be utilitarian stoneware and household crockery and tile.

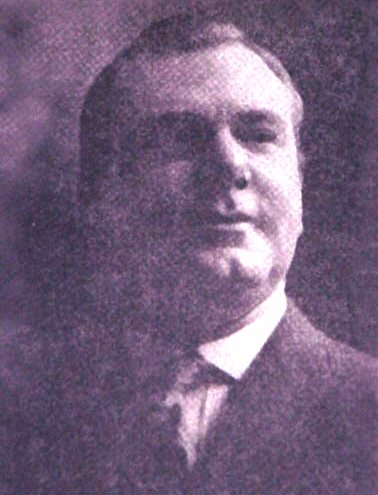

In 1899, the company was incorporated as Fulper Pottery Co. Secretary and treasurer of the company was William Hill Fulper II, grandson of Abram, graduate of Princeton University and veteran of the Spanish-American War. The company at that time was producing more household items such as storage jars and Fire-Proof Cookware.

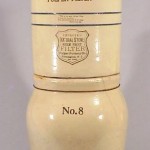

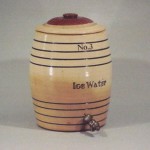

Fulper’s most notable product at the turn of the century was the patented Germ-Proof Filter. Forerunner to today’s “water cooler” the filters were exceedingly popular at a time when public water supplies, when they existed, were not necessarily the most sanitary. Fulper’s Germ Proof Filters were fixtures in railroad stations, offices and schools throughout North America, South America and the West Indies.

Fulper’s most notable product at the turn of the century was the patented Germ-Proof Filter. Forerunner to today’s “water cooler” the filters were exceedingly popular at a time when public water supplies, when they existed, were not necessarily the most sanitary. Fulper’s Germ Proof Filters were fixtures in railroad stations, offices and schools throughout North America, South America and the West Indies.

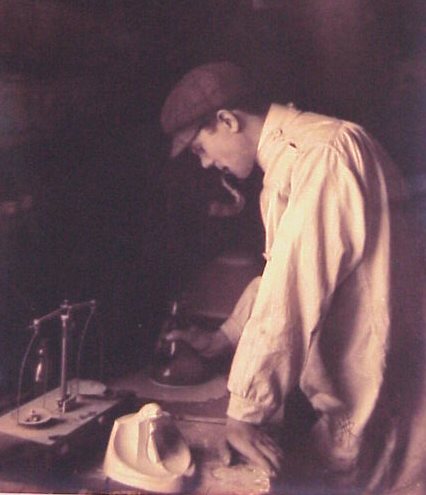

William H. Fulper II was the moving force behind Fulper Pottery’s becoming a prominent manufacturer of art pottery. Fulper’s first artware line was rather casual. Beginning about 1900, Fulper’s master potter John Kunsman began throwing a variety of vases and jugs with simple solid color glazes. These were displayed on the sidewalk in front of the pottery building and sold to Flemington visitors and passersby. Some of Kunsman’s artware was exhibited at the Louisiana Purchase Exposition with a display of Fulper Germ Proof Filters in 1904 and won an honorable mention for design.

William Fulper, possessing an extraordinary gift for marketing and always aware of current trends, saw great profit potential for the Pottery in the field of artware. At the turn of the century, pottery collecting was enjoying great popularity, especially fine examples of antique classical and Chinese pottery. Both private collectors and public museums were scrambling for pots.

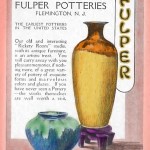

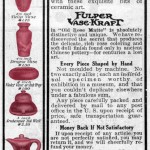

William Fulper sought to capitalize on this collecting trend by providing modern recreations of antique Chinese shapes and glazes. For the glazes, he contracted with Dr. Cullen Parmelee, head of the ceramics department at Rutgers University, to develop Chinese-inspired art glazes. Dr. Parmelee’s glazes were authentic recreations of ancient and rare Chinese glazes and included Famille Rose, Chinese Blue, Seladon, Rouge Flambé and Claire de Lune. These glazes were the backbone of Fulper Pottery Co.’s now renowned Vasekraft art pottery line, introduced in 1909.

However, several of Dr. Parmelee’s glazes were nearly impossible to consistently mass-produce. the copper-based Seladon, Claire de Lune and Rouge Flambé required a hard to control reducing kiln atmosphere to fire correctly, but Fulper primarily fired in an oxidizing kiln. Even the original Famille Rose glaze rarely fired to the pale, true rose-pink it was intended to be.

During 1910, many of Dr. Parmelee’s difficult and costly glazes were either reformulated or discontinued. Also in 1910, William Fulper hired ceramic engineer Martin Stangl to develop new Vasekraft glazes and shapes. While the original Vasekraft line featured Oriental inspired shapes and glazes, Martin Stangl’s shapes were Arts & Crafts styled and his glazes earthy and organic.

One of the first design projects tackled by Martin Stangl at Fulper pottery was the development of Fulper’s now famous Vasekraft lamps. This series of pottery lamps were very novel in that they were topped by pottery shades inset with stained glass shapes and panels. Stangl’s Vasekraft lamps were expensive even then, but were highly popular and were offered by the company from 1911 through 1918.

Martin Stangl’s shapes and glazes coupled with William Fulper’s innovative and tireless advertising campaign propelled the Vasekraft artware line to great recognition and popularity. Fulper Vasekraft products were sold throughout the United States in the most prestigious department stores, gift shops and jewelry stores.

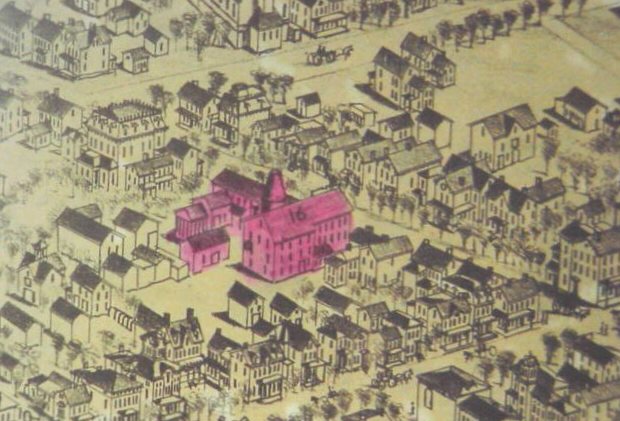

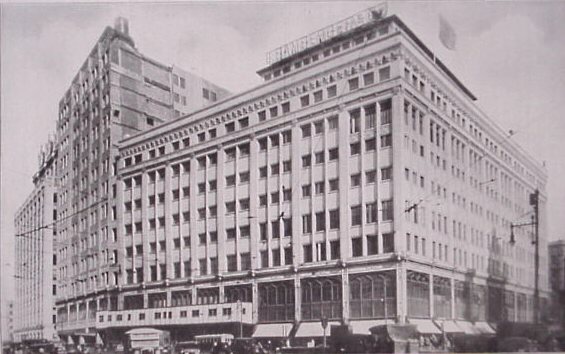

Bamberger’s Department Store in Newark, NJ, one of the

many, many locations that carried Fulper products.

Throughout the 1910s, Fulper’s Vasekraft was highly recognized as an important American art form. Fulper Pottery frequently participated in prominent exhibits of contemporary art and won several awards, including the Gold Medal of Honor at the Panama Pacific International Exposition at San Francisco in 1915.

By Word War I, the popularity of the dark and ponderous Vasekraft shapes was diminishing, so the line was renamed “Fulper Pottery Artware” with newly designed shapes based on English and Spanish Revival styles.

During World War I, Fulper Pottery produced a line of highly successful porcelain dolls and doll heads for American toy manufacturers to replace German porcelain doll heads no longer available. At the end of the war, Germany was able to ship completed doll heads to American manufacturers more cheaply than Fulper Pottery could produce them here, so Fulper discontinued doll head production and introduced a line of novelty porcelain lamps, dresser boxes, ashtrays and boudoir items, marketed as “Fulper Porcelaines”.

In 1924, William Fulper appointed Martin Stangl vice president of the company. Also at that time the company expanded by constructing “Plant No. 2” a few blocks from the original Fulper Factory.

At Plant No. 2 was produced Fulper Pottery’s newly developed Fulper Fayence art and dinnerware lines. The Fulper Fayence dinnerware was America’s first open stock solid-color dinnerware. This line ultimately became Stangl Pottery, and for many years was advertised as “Stangl Pottery, made by Fulper Pottery”

Throughout the 1920s Fulper Pottery Artware continued to be produced at the original factory. By 1926, demand for the Stangl Pottery products had increased to the point that a third production facility was acquired in Trenton, New Jersey.

William Hill Fulper II died suddenly in 1928. The company continued to be run with Martin Stangl as President, Judge George K. Large as Vice President and William Fulper’s widow, Etta, taking her husband’s place as Secretary and Treasurer. In September, 1929, the original factory in Flemington burned, and all production was absorbed by the other two facilities. Fulper Pottery Artware continued to be manufactured at the Flemington Plant No. 2.

During the 1920s and 1930s, Fulper Pottery Artware was designed in Classical, Art Deco and Primitive styles.

In 1935, Fulper Pottery Artware production was ceased at the small remaining Flemington location, and that building was utilized solely as a retail showroom for the company’s ceramic products. After 1935, the company continued to be Fulper Pottery, but produced only Stangl Pottery brand dinnerware and artware.

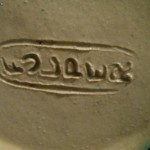

Fulper Pottery Marks