- Tiffany Studios Bamboo Table Lamp on Bamboo Base. Diameter 22″

- Tiffany Studios Daffodil Table Lamp. Diameter 20″

- Tiffany Studios Dogwood Table Lamp. Diameter 18″

- Tiffany Studios Dragonfly Table La

- Tiffany Studios Greek Key Table Lamp. Diameter 19″

- Tiffany Studios Peony Table Lamp. Diameter 22″

- Tiffany Studios Poppy Table Lamp on Wire Mesh Base. Diameter 17″

- Tiffany Studios Wisteria Table Lamp. Diameter 18″

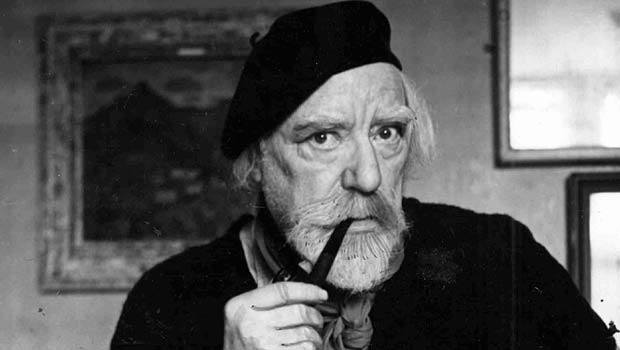

Louis Comfort Tiffany was born on January 17, 1848, the son of Charles Lewis Tiffany, and began his career as a painter in the 1860s and 1870s. He founded his own firm, Tiffany Studios, in 1885 and focused on art glass. Earlier, Louis Comfort Tiffany had already registered for a patent on a new glassmaking technique of combining different colours in opalescent glass to create vibrant, multidimensional hues of colour never before seen in glass. With the help of chemists, craftsmen, and glass designers, he was able to make stained glass in over 5000 different colours and textures. This challenged the traditional approach of painting on glass to create multicoloured effects.

Tiffany became an enthusiastic supporter of the European Art Nouveau movement, challenging the current Victorian ornate style. Art Nouveau used free-flowing designs based on nature that exemplified the characteristics prevalent in Tiffany’s earlier creations as a landscape painter. The use of light, colour and nature assumed greater significance in Louis Comfort Tiffany’s work as he developed his unique approach to Art Nouveau. Tiffany’s work was displayed in Europe at the most important venue for the introduction of Art Nouveau, Siegfried Bing’s L’Art Nouveau.

In an effort to reach the interiors of a greater population, Tiffany began to design lamps to allow more people to enjoy art and beauty in their own home. Coloured glass, Tiffany’s lasting love and challenge, found fresh scope and inspiration. While the windows served to transmit the light of day, the lamps represent a new source of illumination independent of daylight.

Fabrication of Tiffany Studios lamps began in 1885, with the majority of them being made between 1895 and 1920. It was not until 1899 that Louis Comfort Tiffany publicly introduced the lamps for sale.

As one of America’s most influential artists, designers and craftsmen of the century, Tiffany wanted to bring decorative arts to the same status as fine arts. The lamps of Louis Comfort Tiffany signify this quest to bring beauty into the home. After collaborating to light the first movie theater, friend Thomas Edison suggested the idea of making electric fixtures. Tiffany soon began to create lamps as small versions of his exquisite stained-glass windows and developed the idea into a new art form. He first began experimenting with lamps in 1895 although they were not offered for sale in his showroom until 1899. Tiffany’s lamps, most of which were made between 1897 and 1920, were and still are recognized for their superior design and handcrafted details. In addition to bringing beauty to the masses, Tiffany also made discoveries in the process for formulating glass. Tiffany developed a unique process that created bolder colours, opalescent sheens and a broader range of textures for artisans.

He patented four types of glass over a period of two decades and worked with teams of craftsmen to manufacture stained-glass windows, lamps and lamp bases. He used the leading inherent in the design of his leaded glass lamps to add to the naturalistic forms, letting it represent, for example, the stems of plants.The motifs in Tiffany’s elaborate lamps were inspired by his love of nature and the names of his lamp designs are indicative as they include the dragonfly, dogwood, peacock, peony, daffodil, laburnum, wisteria, poppy, acorn, water lily, and more. Tiffany stated that his lamps allowed more people to enjoy the elements of nature, such as flowers in bloom, all year long in the beauty of his glass.

Dealers classify Tiffany lamps into distinct groups.

The term Favrile, meaning handcrafted, is associated with the first and simplest shades. An early patent obtained by Tiffany under the name Favrile encompassed several types of glass used in the manufacture of stained-glass windows as well as leaded and blown shades. However, the term now is associated with blown forms such as shades and other types of hollow ware. Favrile pieces are generally inscribed L.C.T. or Favrile, while shades made from leaded glass are labeled with impressed metal signature tags.

The term geometric is applied to the group of leaded-glass shades with the simplest designs, and includes standard geometric shapes such as squares, triangles, rectangles, ovals, ellipses, and rhomboids used on panel, cone, and globe-shaped shades. Unlike blown shades, the geometric and all ensuing groups were fabricated from pieces of poured glass cut in segments, edged with copper foil and leaded or soldered together to form a complete unit. A patinated bronze finish was then applied to the lead or solder lines. The geometric group is divided into two basic types: shades made from a large number of small glass pieces and those made from a limited number of large glass pieces, such as turtleback tiles and Favrile Fabrique panels.

The transition to flowers group serves as a bridge between the geometric and floral shades. It includes globe-shaped shades of basic geometric design with added botanical motifs. The group is divided into two categories: geometric shades with borders or belts of flowers and vines, and shades with scattered floral or leaf patterns on geometric backgrounds.

Botanical patterns, which were introduced in moderation on shades in the transition group, are employed en masse in the cone group. As described by Tiffany Studios in a 1906 catalogue, cone shades are straight-sided with circular rims. They are easier to manufacture than leaded shades with curved or rounded sides, hence the greater number of shades in this category. While cone-shaped shades are found in the geometric group, they are classified there by design rather than form. Another natural motif applied to cone-shaped shades is the dragonfly. This insect design is developed further in the flowered globe and irregular lower border groups.

The flowered globe group is more complex in construction than the preceding group of cone-shaped shades. In terms of decorative progression, their shape permits a more natural rendering of the botanical and insect motifs. Tiffany Studios referred to this type of “domed” in its 1906 catalogue. Globes range in size from twelve inches to twenty-eight inches in diameter.

The shades in this group take on a more naturalistic form, with flowing, serpentine rims. The uninterrupted metal edge and stylized band of the preceding groups have been replaced with a curvilinear lower border. Except for the panel shades used with the grape trellis motif, all the shades in this group are globular in shape. The natural termination of leaves, fruits, insect bodies, and flowers give shades in the irregular lower border group an Art Nouveau character often associated with Tiffany Studios.

At the final phase of development are shades with both irregular upper and lower borders. In this group the artificial straight edge of the aperture is replaced by an openwork crown that simulates tree branches or shrubbery. Finials have been eliminated, and light and heat are diffused through the crown. The combination of the irregular upper and lower border is the consummate Tiffany Studios Shade.

At first, Louis Comfort Tiffany used glass used by outside firms but this did not give him total satisfaction. As his fascination with glass grew, he experimented with lustre techniques, largely inspired by the natural iridescence of ancient Roman glass. He patented his first glass-lustre technique in 1881. Favrile glass, the trademark for Tiffany handmade glass, resulted from these experiments and, with the exception of Tiffany lamps, it is the ware for which he is best known.

Tiffany set up his own glasshouse at Corona, Long Island and put a brilliant Englishman, Arthur J. Nash, in charge. His previous companies had all been concerned with interior decoration. This one, Tiffany Furnaces, concentrated on decorative blown glassware. In 1893 Tiffany introduced his first hand blown-glass vases and bowls, which he called “Favrile.” The word Favrile was taken by Tiffany from an old English word for hand made.

Tiffany Favrile glass quickly gained international renown for its surface iridescence and brilliant colors. Tiffany, no craftsman himself, died considerably less wealthy than he began, because of his own fascination with the capabilities of glass in the furnace. He was not content to leave the experiments to his skilled workers and he would not abandon his own ideas even when Nash was satisfied, after repeated efforts, that they would not work. Such interference was not cost effective, but it was symptomatic of what he was trying to do. He was a leader and Tiffany glass was never a shadow of the work of other men.

Tiffany developed a whole range of unique glassware by trying out and perfecting new techniques in the furnace. The glass itself was of the best quality, its colours achieved by the addition of metallic oxides, variable by temperature within the furnace. His lustre technique, with its iridescent effect, was the most important because it was his hallmark, used in many different wares. This involved dissolving salts of metallic oxides in the molten glass, so creating the chosen colours, soft greens, blues, golds, etc. The metallic content was then brought to the surface by subjecting the glass to a reducing flame and spraying with another chloride. This treatment caused the surface to crackle into a profusion of tiny lines that refracted light. The skill of the blower was paramount in this, because Tiffany glass was free blown. Speed was necessary to achieve the desired effect before the molten glass cooled.

- Tiffany Favrile Glass Adventurine Vase. Height 12″

- Tiffany Favrile Glass Double Gourd Vase. Height 8.75″

- Tiffany Favrile Glass Flower Form Vase. Height 13.25″

- Tiffany Flower Form Favrile Glass Vase On Bronze Mount. Height 16.5″

- Tiffany Favrile Glass Jack in the Pulpit Vase. Height 22″

- Tiffany Favrile Glass Millefiore Vase. Height 6″

- Tiffany Favrile Glass Paperweight Vase. Height 6″

- Tiffany Favrile Cameo Glass Paperweight Vase. Height 5″

- Tiffany Favrile Glass Peacock Vase. Height 22.5″

With intricate Tiffany specialties like the peacock feather motif or a jack-in-the-pulpit vase, executing this technique was very difficult. Specialty glassware is rare and therefore expensive. Lava glass, with its glorious golden trails on rough-surfaced basalt, and Cypriote glass, rolled in fragmented crumbs of glass to give the impression of old Roman glass, are examples of iridized pieces of Tiffany ware. Damascene glass is another such specialty, developed c.1910, which incorporates striped of golden lustre giving the appearance of damascened steel when blown into wavy stripes. Agate glass exhibits a marbled effect resulting from a mixture of various coloured glasses.

Many Tiffany specialties were developed from ancient forms and styles. For example, the technique for creating millefiori had been used 2000 years ago, but not by Tiffany’s methods or with his lustre finish. The closely packed “thousand flowers ” of millefiori, most familiar in French paperweights, were formed by fusing tiny rods of coloured glass. Tiffany did not place segments of these rods in close proximity as in paperweights. In the celebrated Tiffany floral vases, a patch of opalescent glass and the whole was reheated, allowing the well-separated flowers to be moulded into the body before the piece received its iridescent finish.

Some items decorated in this manner were cased with a layer of clear glass, sometimes called Tiffany paperweight glass. Aquamarine glass, made in much the same way, was embedded with marine decoration and wavy green sea vegetation occasionally with fish or pebbles. In these works, the heavy green glass was intended to simulate the sea, and those with fish and sea life are the most rare.

These vases produced c 1905-1915 were made according to paperweight making techniques but what would be a flaw in a paperweight, i.e. bubbles of air, adds to the naturalistic effect as bubbles rising to the surface of the water.

In 2002, a Tiffany Favrile aquamarine Goldfish vase, one of only 2 known to exist, sold for $532,000 setting a new record for Tiffany glass.