Caithness Glass was founded in 1961 at Wick in the far North East of Scotland, by the late Robin Sinclair, local landowner and politician. The idea was sparked off by an unemployment crisis in this area when the farming and herring fishing industries collapsed in the mid 20th century.

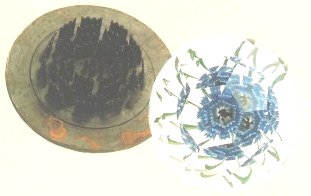

Crimps like the one on the left are used to make many of the designs. This is Cornflower by Helen MacDonald, with its crimp.

The Sinclair family was closely concerned with the county of Caithness and when the government started to build a nuclear reactor near Thurso in the late 1950s Robin Sinclair looked for an enterprise that would create local employment for the town of Wick. Something that would find a market with the tourists who came to this remote part of Scotland, and could be easily exported, was Art Glass. It converted raw materials which were readily available into prestigious products by means of artistry and skill. Robin decided to seek Government sponsorship to build a glass factory.

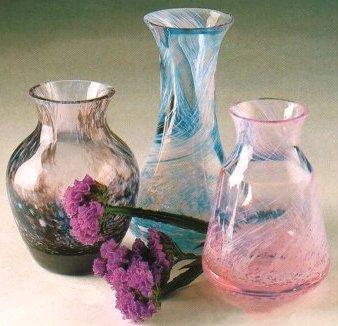

A new purpose-built factory was eventually funded by the Scottish Industrial Estates agency, and leased to Caithness Glass in 1961. Initially the Company made bowls, vases and drinking glasses in the popular Scandinavian style of the time. They soon became well known for their distinctive coloured glass designs, which echoed the haunting colors of the Scottish landscape.

Caithness started producing paperweights in the factory experimenting with abstract designs which could be reproduced in large numbers. The abstract paperweights which were designed for Caithness, in a tradition which continues today, were not random placings of bubbles and colored inserts like many abstract paperweights produced elsewhere. Each piece was designed to be a production run, sometimes as many as 650 of one design, and sometimes many thousands (the unlimited editions). Crimps and special tools were designed and detailed drawings and instructions prepared for each design.

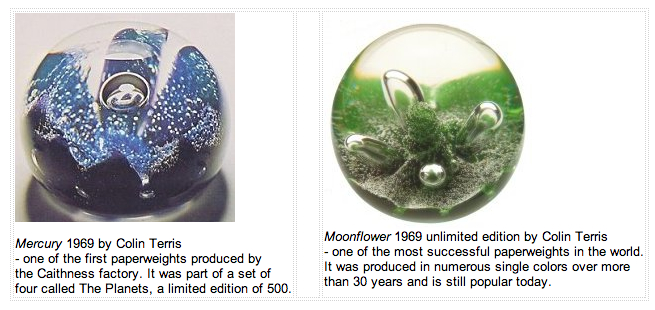

In 1969 was launched the first set of modern paperweights – The Planets, a set of four abstracts paperweights representing Mars, Mercury, Saturn and Venus and each produced in a limited edition of 500. These quickly sold and the company built on this success by launching six new paperweights in 1970. There was a second Planets set (Uranus, Jupiter, Neptune, and Earth) and one called “Orbit” and all five were again limited editions of 500. The first unlimited edition, Moonflower, was produced that year, and continued to be produced for over thirty years. Moonflower was the most successful paperweight ever made by Caithness and probably the most successful in the world in terms of numbers sold.

With all the important events going on in relation to paperweights, it is easy to forget that Caithness originally made its name as a successful producer of vases, bottles, and bowls. In 1968 the company was awarded the Queen Mother’s Royal Warrant (meaning they were the recognised supplier of glass to the Queen Mother) and the company continues today to make a beautiful range of glassware, which now includes paperweights and small clocks set in glass spheres.

With all the important events going on in relation to paperweights, it is easy to forget that Caithness originally made its name as a successful producer of vases, bottles, and bowls. In 1968 the company was awarded the Queen Mother’s Royal Warrant (meaning they were the recognised supplier of glass to the Queen Mother) and the company continues today to make a beautiful range of glassware, which now includes paperweights and small clocks set in glass spheres.

Until 1969 Caithness had only one factory, the one at Wick; but in 1969 a new factory was opened at Oban, many miles away on the West coast of Scotland. This factory focussed primarily on art glass, but they did help out with paperweight production from the early 1970s to the 1990s.

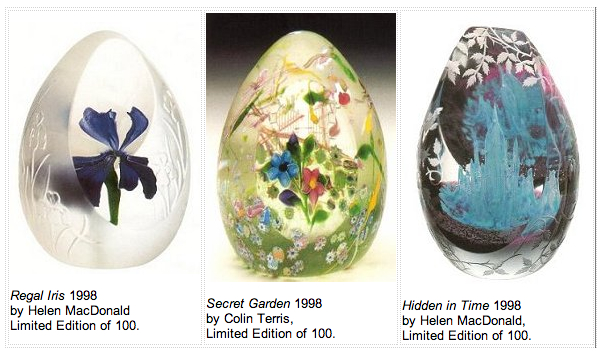

Caithness has made a speciality of combining an internal theme, either lampwork or abstract, together with deeply engraved designs on the outside integrated with the theme. Sometimes the outside is also acid etched, as in Regal Iris (shown below) by Helen MacDonald who designed her first paperweight for Caithness in 1978. Sometimes the engraved design is on the back of the paperweight, so that it shows through the cut facet as part of the design, as in Secret Garden below. And sometimes the engraved design surrounds the paperweight, like Hidden in Time below.

In 1979 Caithness Glass expanded into another new factory, this time in Perth, Central Scotland. Perth became their Headquarters, combining a major visitor center, viewing gallery, museum of Caithness paperweights, and the glass factory. The main production center for Caithness paperweights moved to Perth, with Wick and Oban concentrating on art glass. However a small number of paperweights continued to be made at Wick and at Oban.

An interesting feature of this three-location production process was that the three factories tended to use different glass, and this can be detected using an ultra-violet lamp, because they fluoresce differently. When the Oban factory made paperweights, which they did between the early 1970s and early 1990s, they used only soda glass without any lead content. The Perth factory used glass which did contain lead until 1990, when they stopped including lead oxide because it was believed to be environmentally unfriendly, and because it reacted with some of the colors. Lead oxide tended to give the reds and yellows a grey or even a black tinge, and a purer color can be obtained with soda glass which contains no lead. The lead oxide was replaced with barium oxide.

However the Wick factory went on using glass containing lead oxide until 1999. The same paperweight design could be made with or without the lead oxide content, depending which of the three factories made it.

A major development occured in the early 1980s, when Caithness bought the Whitefriars Glass paperweights business, together with their molds, tools, canes, documents, and all rights in the name Whitefriars, its logos and trademarks. This followed the sad closure of the historical Whitefriars Glassworks of James Powell and Sons in London in 1980.